Looking to turn your digital designs into real-world objects quickly and efficiently? A 3D print service makes it easy. Upload your CAD files, get an instant quote, and start printing high-quality parts. This article covers how these services work and what you can expect.

Key Takeaways

Professional online 3D printing services streamline the production process by allowing users to upload CAD models for an instant quote, enhancing efficiency and project management.

A diverse range of 3D printing technologies, such as FDM, SLS, and SLA, offers tailored solutions for different applications, from prototypes to production-grade parts.

Quality assurance, including relevant certifications, is fundamental to delivering high-quality 3D printed components that meet stringent industry standards and client specifications.

Professional Online 3D Printing Services

Professional online 3D printing services have transformed how we produce both: prototypes and production-grade parts. These services specialize in delivering high-quality outputs that cater to various needs, from functional prototyping to end-use production parts. The convenience of simply uploading your CAD files and receiving instant quotes has streamlined the manufacturing process. This allows for faster and more efficient project management.

Key processes such as Fused Deposition Modeling (FDM) and PolyJet are central to these services, offering diverse solutions for different applications. FDM is recognized for its cost effectiveness and ability to produce durable parts. PolyJet, on the other hand, shines in creating high-resolution prototypes with intricate details. This variety ensures that customers can choose the best technology for their specific project needs.

Whether you need a single prototype or a batch of production parts, professional online 3D printing services provide a reliable and efficient solution to bring your designs to life.

Instant Quotes for Custom Parts

One of the standout features of modern 3D printing services is the ability to obtain instant quotes for custom parts. By simply uploading your CAD files, you can receive a detailed quote that includes factors such as part volume, complexity, material choice, printing technology, and post-processing requirements. This transparency ensures there are no hidden costs and allows for real-time updates during the quote process.

The process is designed to be as user-friendly as possible. After uploading your CAD file, you can confirm the specifications and select a lead time that suits your project timeline. This immediate feedback is invaluable for rapid prototyping and production planning. It enables you to make informed decisions quickly and efficiently.

This seamless integration of quoting, production, and delivery makes online 3D printing services an attractive option for both small and large scale projects.

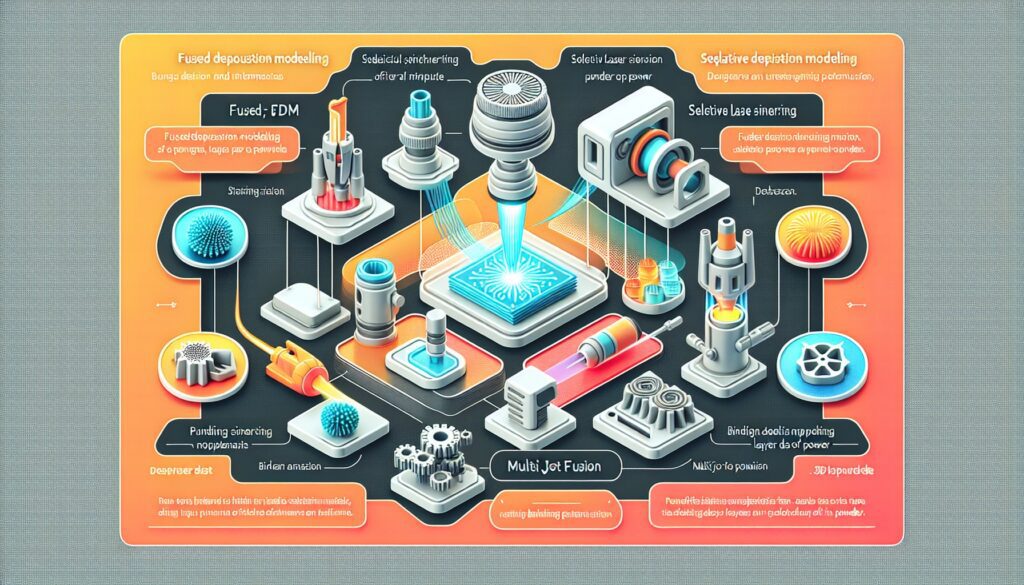

Diverse 3D Printing Technologies

The world of 3D printing is vast, with a plethora of technologies available to cater to different needs. Among the key technologies are Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Stereolithography (SLA). Each of these technologies has its unique strengths and applications. It’s essential to choose the right one for your project.

Fused Deposition Modeling is what we use here at Baysinger’s Additive Manufacturing. It’s widely used for its affordability and ability to create durable parts. However, it does have visible layer lines that impact the aesthetic quality. On the other hand, Selective Laser Sintering (SLS) excels in producing parts with complex geometries and internal features without the need for support structures. Thanks to the unfused powder, it provides the necessary support during the printing process.

Technologies like Stereolithography (SLA) and Multi Jet Fusion (MJF) are known for their high resolution and precision. This makes them ideal for intricate designs and applications requiring smooth finishes. The downside to these technologies is the lack of durability. The layers are very small to get the smooth finishes and each layer adds a weak point to the part to break.

Understanding the capabilities of these diverse technologies allows you to choose the most suitable method for your specific requirements. It ensures the optimal results for your 3D-printed parts.

Rapid Prototyping Solutions

Rapid prototyping’s speed and efficiency have revolutionized many industries. With 3D printing, parts can be produced in a matter of hours, significantly accelerating the prototyping process and reducing time-to-market for new products. this rapid turnaround is crucial for businesses looking to stay competitive and responsive to market demands.

Custom 3D printed components play a vital role in iterative design processes, allowing for tangible models to be tested and evaluated quickly. This iterative approach helps in validating and refining designs before committing to a large-scale production. Conditions minimizing risks and costs associated with product development. For example, consumer goods companies can rapidly prototype and test new products, ensuring they meet consumer expectations before mass production.

Industries like aerospace also benefit from rapid prototyping, where the quick creation of prototype components enables faster testing and validation of new designs. Leveraging rapid prototyping capabilities enables businesses to innovate more effectively and expedite the market introduction of high-quality products.

Production-Grade Parts

3D printing is not limited to prototyping; it also excels in producing production-grade parts. This capability is highly valuable across various industries, including aerospace, automotive, and medical. In the aerospace sector, 3D printing is used to create functional prototypes and lightweight components. 3D printing enhances components’ performance and reduces weight.

In the automotive industry, 3D printing is utilized for tooling and producing end-use parts, meeting specific design requirements with high accuracy and consistency.

In medicine, 3D printing is used to create customized prosthetics and surgical guides tailored to individual patients. Great for the technology’s precision and customization capabilities.

The cost-effectiveness of 3D printing for production runs is another significant advantage. the ability to produce parts on-demand and with high accuracy reduces the need for large inventories and minimizes waste. This efficiency makes 3D printing an attractive option for production-grade parts. 3D printing offers both economic and performance benefits.

Wide Range of Materials

One of the strengths of 3D Printing is the wide range of materials available for different applications. From metals to plastics, the variety of materials ensures that you can find the perfect match for your specific needs. For instance, over 80 materials, covering a broad spectrum of project requirements, are available for instant quoting.

Plastics Materials

The types of materials include plastic, resin, metal, and various photopolymers. Each material offers unique properties. Plastic materials like Nylon, ABS, ASA, TPU, and ULTEM cater to different engineering applications. Some material properties included flexibility, heat resistance, and durability. ULTEM, for example, is known for being tough and heat-resistant, making it ideal for demanding applications.

Metal Materials

Metal 3D printing materials, such as aluminum and titanium alloys, provide options for creating strong and lightweight components. The ability to utilize millions of combinations of materials, finishes, and certifications further enhances the customization possibilities, ensuring that your 3D-printed parts meet the highest standards of performance and aesthetics.

Post-Processing Options

Post-processing is a crucial step in 3D printing. It can significantly improve the surface finish and functionality of printed parts. Techniques such as sanding and polishing remove material to create a smooth surface. These methods enhance the aesthetic and tactile quality of the parts.

Support removal is a post-processing step in 3D printing but as a 3D printing service, all support will be removed before you receive the object. That being said, if too much support is needed to print your part, most 3D printing services will either apply surcharges for the extra time needed or advise that this file is redesigned to conform to the 3D printing process. The 3D printing service will advise on the best course of action.

Chemical treatments like vapor smoothing achieve a polished finish without removing material. It redistributes the surface molecules instead.

Tumbling can also enhance the finish of multiple parts simultaneously. This highly efficient method can reduce a ton of labor involved in post-processing. Of course, the downside to this method

These various post-processing options allow for a high degree of customization and refinement. Your 3D-printed parts will meet all necessary specifications and standards.

Flexible Manufacturing Capabilities

The flexibility of 3D printing in a manufacturing is one of its greatest strengths. This technology allows for the economical production of match sizes ranging from a single unit to a few thousand, Making it suitable for both small and large-scale projects. The ability to adapt to various materials, colors, and production sizes simultaneously enhances the versatility of 3D printing.

This flexibility is a key component of the Smart Factory concept, which aims to create adaptive and efficient manufacturing processes with the support of manufacturing partners. Recent surveys indicate that the use of 3D printing and additive manufacturing for production is expected to grow significantly. It supports 3D printiing’s capability to handle both single parts and large production runs.

This adaptability ensures that 3D printing can meet the evolving needs of the manufacturing sector, providing solutions that are innovative and practical.

Applications of 3D Printing

The applications of 3D printing are vast and varied, spanning numerous industries such as automotive, aerospace, healthcare, and jewelry. In the automotive industry, 3D printing is used for low to medium volume production runs, allowing manufacturers to meet specific design requirements and reduce production times.

The aerospace sector leverages 3D printing to create components with complex geometries, enhancing performance and reducing weight. In healthcare, 3D printing enables the creation of customized medical components, such as prosthetics and surgical guides, tailored to individual patients’ needs.

This technology also allows for the consolidation of multiple parts into a single assembly, simplifying production processes and reducing costs. Enabling more intricate and complex designs, 3D printing continues to expand the possibilities in manufacturing.

Advantages of Using Online 3D Printing Services

Online 3D printing services offer numerous advantages, making them an attractive option for various projects. One of the primary benefits is the ability to create complex geometries that traditional manufacturing methods cannot achieve. The capability allows for greater design freedom and innovation, enabling the production of parts that are both functional and aesthetically pleasing.

The print-on-demand nature of 3D printing services reduces the need for extensive inventory storage, leading to significant cost savings. Additionally, the process minimizes waste by only using the necessary materials for each printed part. contributing to a more environmentally friendly manufacturing approach. The convenience of accessing local service providers for 3D printing projects further enhances this benefit, reducing transportation costs and turnaround times.

Moreover, 3D printing often requires fewer steps compared to traditional manufacturing methods, lowering overall manufacturing costs. These advantages make online 3D printing services a practical and efficient choice for a wide range of applications, from rapid prototyping to full-scale production.

How to Optimize Your 3D Print Designs

Optimizing your 3D print designs is crucial to ensure the best possible outcome. One key tip is to incorporate arches in your designs which can prevent sagging in channels and holes by leveraging gravity for support. Additionally, managing at least a 45-degree angle from the build plate helps minimize the need for support structures, simplifying the printing process and reducing material usage.

For metal parts produced by direct metal laser sintering, a height-to-wall thickness ratio of 40:1 is recommended to ensure strength and stability. Following these design optimization tips will help you achieve high-quality 3D printed parts that meet your specific requirements.

For more information on optimizing your designs, check out our guide called How to Design for 3D Printing in 2024. It goes over many design features that will ensure your parts are designed to be 3D printed.

Summary

In summary, online 3D printing services offer a revolutionary approach to manufacturing, providing unparalleled convenience, flexibility, and innovation. From obtaining instant quotes to leveraging diverse 3D printing technologies, these services cater to a wide range of needs, from rapid prototyping to production-grade parts. The availability of a vast array of materials and post-processing options ensures that your designs can be brought to life with the highest quality and precision.

By understanding the benefits and capabilities of 3D printing, businesses and individuals can optimize their designs and take full advantage of this transformative technology. Whether you are looking to create intricate prototypes, durable end-use parts, or custom components, online 3D printing services provide the tools and expertise needed to turn your ideas into reality. We encourage you to explore these services and see how they can enhance your projects and streamline your manufacturing processes.

Frequently Asked Questions

How do I get an instant quote for my 3D printed parts?

To get an instant quote for your 3D printed parts, simply upload your CAD files to our Contact Form. A team member will breakdown the cost of your job and send it back to you via email. This process ensures a quick and easy way to understand your project’s expenses.

What factors influence the cost of 3D printing services?

The cost of 3D printing services is primarily influenced by part volume, material choice, printing technology, and post-processing requirements. Understanding these factors can help in budgeting for your project effectively.

What types of materials can be used for 3D printing?

A diverse array of materials is suitable for 3D printing, including metals, plastics, resins, and photopolymers, with options like Nylon, ULTEM, aluminum, and titanium alloys serving specific needs. This versatility allows for tailored solutions in various applications.

How can I ensure the quality of my 3D printed parts?

To ensure the quality of your 3D printed parts, implement certifications like ISO 9001:2015 and AS9100, and conduct thorough inspection processes to verify dimensional accuracy and compliance with specifications. This approach will help you achieve reliable and high-quality outcomes.

What are the advantages of using online 3D printing services?

Using online 3D printing services provides significant benefits, such as creating intricate designs with minimal waste and cost savings. Additionally, you gain the convenience of print-on-demand services and can access local providers easily.